Zodiac

Special Features

|

Ballistic Recovery Systems (BRS)

The parachute system is designed to protect occupants

in the event of an emergency by lowering the aircraft to the ground after

deployment. Ballistic Recovery Systems (BRS) revolutionized general aviation

safety by providing an alternative measure of safety to occupants.

To deploy the parachute, a person must use

approximately 35 pounds of force on the red handle to set off a magnesium

charge that ignites a solid-fuel rocket. The rocket blows out a hatch where

the BRS is stored. As the rocket deploys, the aircraft will slow as the

embedded BRS harness straps unzip from both sides of the fuselage.

Within seconds, the parachute will unfurl to assist

the aircraft descent. |

|

|

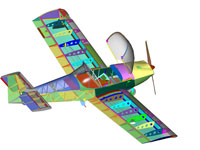

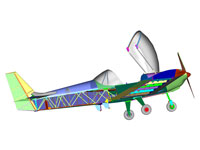

Redesigned - the Zodiac CH 650 B:

The original Zodiac was designed by renowned aeronautical

engineer Chris Heintz in the mid-eighties. The design has been a popular

kit-plane since then, marketed and produced in the US by Zenith Aircraft

Company. More than 1,000 Zodiac aircraft are flying throughout the world

today. Over the years, the Zodiac design has evolved as it was first

certified and then manufactured as a ready-to-fly aircraft in Canada, Europe

and South America, as per local regulations, and now in the USA.

The

Zodiac CH 601 XL aircraft was redesigned for the Light Sport Aircraft category in 2004. The

Zodiac CH 650 B is different than the XL. The 650 B incorporates many changes that were made to the 601 series in Europe

and around the world. The 650 B incorporates the best of everything.

The Most noticeable difference is the canopy and rudder. Other changes

includes lowering of the trailing edge of the wings (lowers the nose of the

aircraft for better visibility), control changes (more balanced), tougher

fuselage (good for flying schools), new canopy latching - locking system

(easier to close and open the canopy), and a lot more. The B designation

incorporates all the latest airframe upgrades which includes a tougher

airframe and ailerons balance weights.

Lightening Protection:

Lightning

protection has become a big concern over the years with many new-generation

light aircraft.

"A

growing new class of kit-built composite aircraft also raises some concerns.

Because owner-assembled, kit-built aircraft are considered by the FAA to be

"experimental," they are not subject to lightning protection regulations.

Many kit-built planes are made of fiberglass or graphite-reinforced

composites. At Lightning Technologies' laboratory, we routinely test

protected fiberglass and composite panels with simulated lightning currents.

The results of these tests show that lightning can damage inadequately

protected composites. Pilots of unprotected fiberglass or composite aircraft

should not fly anywhere near a lightning storm or in other types of clouds,

because non-thunderstorm clouds may contain sufficient electric charge to

produce lightning."

When

certifying the Alarus in the early 90's, Zenair consulted with Lightning

Technologies, Inc. to assist with the process of full FAA FAR 23

compliance. Today, the new Zodiac 650 B benefits from past

research and development and incorporates lightning protection technology

and equipment similar to the Alarus aircraft.

For more

details, please visit:

http://www.lightningtech.com/d~ta/faq1.html

|

|

|

|

|

|

The Engine:

FAA certified under part 33, allowing IFR operations.

Engines are factory new.

|

|

|

ENGINE CERTIFIED UNDER FAA PART 33 |

|

|

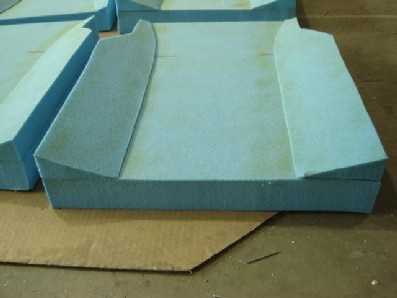

Seat Foam |

|

|

Temper foam, also known as memory foam, was first commercialized during the

mid 60’s as a result of NASA’s AMES Research technology transfer program.

This open-cell variety of flexible polyurethane foam (FPF) was

distinguished by properties allowing it to redistribute the G-Force suffered

by astronauts during take-off and re-entry, and providing commercial pilots

a more comfortable seating surface during long flights. Although

Temper foam production technology has been available for more than 35 years,

commercial products have only recently been made widely available to

consumers.

Temper foam is typified by its slow recovery after compression. When a

weighted object (for example, the human body) is positioned on Temper foam,

the foam progressively conforms to the shape of the object, and after the

weight is removed, the foam slowly reassumes its initial shape. Due to this

gradual recovery, Temper foam also can be described as “slow recovery” foam.

Other

characteristics include Temper foam’s ability to dampen vibration as well as

absorb shock. This latter performance characteristic is confirmed in the

laboratory using ball rebound tests. Ball rebound of less than 20% (compared

to 50% – 60% with other varieties of FPF) supports the description of Temper

polyurethane foam as “dead” or “low-resilience” foam, in that it lacks the

surface “springiness” of other FPF products. In fact, certain Temper foam

products claim to absorb up to 90% of impact.

In

addition to these key advantages, Temper foam also react to body temperature

and ambient temperatures, softening with heat and more easily adjusting to

body contours.

In

the Alarus, Temper type foam is used and is part of the FAA

approved Type Design..

The same foam is available as an option for the Zodiac |

|

|

|

|

|

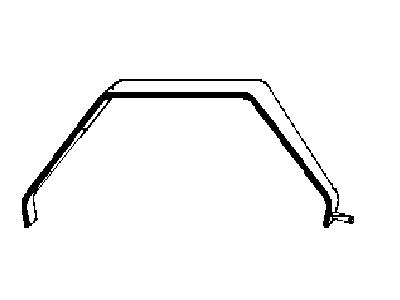

Landing Gear:

The simple

one-piece aluminum

spring gear of the Alarus has been well

tested in the field as many flying schools

throughout the world

are using the aircraft as a primary and

IFR trainer.

The Zodiac gear is similar. Extra tough and simple.

|

|

|

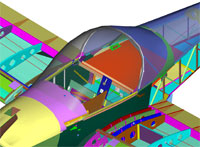

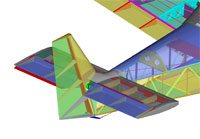

Structural Load Testing of the Zodiac: |

|

|

The ZODIAC design is the product of extensive

research and development, and the result of professional engineering by

Chris Heintz,

a leading designer of light aircraft. The modern design makes use of

advanced technologies, while using proven design concepts and simple systems

for easy assembly and maintenance. A professional design, the ZODIAC

structure has undergone a complete and rigorous flight test and design

stress analysis, as well as load testing of critical components: |

|

|

|

New structural tests again confirms the structural

strength of the 650 B.

Tests were approved and witness by an independent

structural engineer.

|

|

|

|

Avionics:

The Fast Stack Approach

Harness makes it simple to upgrade as many avionic systems are incorporated

into the Pro-G Wiring System. It's like a plug-and-play system. Each cable

and lead is clearly marked. Instead of having hundreds of individual wires

behind your panel, you have a few. The installation is clean and easy to

maintain.

When a significant

amount of Garmin and other avionics are installed, the Approach Pro-G system is used. |

|

|

.

Transponder-Encoder and pitot static

tests:

In order to meet requirements of FAR 91.411

(...No

person may operate an airplane, or helicopter, in controlled airspace under

IFR unless...Within

the preceding 24 calendar months, each static pressure system, each

altimeter instrument, and each automatic pressure altitude reporting system

has been tested and inspected and found to comply...). Tests are signed off by an FAA certified person before delivery. Log

book entry must be made.

In order to meet requirements of FAR 91.413 (No

persons may use an ATC transponder.....unless, within the preceding 24

calendar months, the ATC transponder has been tested and inspected and found

to comply...). Tests are signed off by an FAA certified

person before delivery. Log book entry must be made. |

|

|

ELT:

ELT's are tested and inspected in compliance with FAR 91.207. ELT can be

turned ON at the panel.

|

|

|

|

|

|

|

|

|

|

|

|

Aircraft Inspection & Maintenance:

Due to the wide range of available avionics, the top part of the instrument

panel can be easily removed for inspection and maintenance. Rear fuselage

can be accessed through a bottom inspection panel about 2x2 feet big or by

moving the seat backs forward. Other inspection panels are located under the

wings for aileron system and fuel inspection. |

|

|

|

|

|

Aircraft Ground Handling:

Nose wheel area is designed so that standard type aviation systems can be

used to move the aircraft.

|

|

|

|

|

|

Aircraft Ground Power Plug:

Located behind the wing, away from the propeller. |

|

|

|

|

|